Background

People react differently to bad news. Some let it get the best of them, but others, like David Ward, turn it into something positive that has many positive and lasting effects on the environment and economic development. When Mr. Ward, a carpenter from the state of Oregon in the United States, found out from his doctor that exposure from building materials made his “blood chemistry read like a list of industrial solvents,” he set out to find less damaging materials with which to build homes. Knowing that traditional bricks of mud mixed with plant fiber are an effective building material, he began to investigate ways of using straw, an agricultural waste product from harvesting cereal grains such as rice and wheat, to construct building materials.

Invention

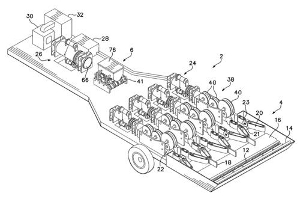

a straw cable, which is woven into mats and

compressed into robust building panels

(Photo: ASET/StrawJet Project)

Mr. Ward’s idea in and of itself was not new. There are already industrial processes to produce compressed straw building blocks. However, they are carried out in factories which make such processes expensive and waste producing. Mr. Ward’s creative vision was to move the process from the factory to the field. Doing so eliminates factory overhead and by using uncut, uncrushed straw straight from the field, the resulting product is of a much stronger composition. In 2005, after thirteen years of development and with the help of Oregon State University and a US$70,000 grant from the United States Environmental Protection Agency (EPA), Mr. Ward’s vision turned into reality when he and a group of sustainable building enthusiasts built the first prototype StrawJet Harvester. Mr. Ward formed the non-profit Ashland School of Environmental Technology (ASET) to help in the StrawJet System’s development, and spent 2006 and 2007 refining the invention for production.

The StrawJet Harvester takes waste stalks and creates a continuous, tightly wrapped five centimeter rigid straw cable that is compressed and bound with polyester twine. An innovative complementary binding machine assembles four cables in a square pattern and binds them together with a clay and recycled paper-pulp bonding agent. The cables are then wrapped together with yarn into a variety of low cost, fully recyclable, durable, non-toxic and insulating building materials such as beams or construction panels. Made right there on the field, no glues, chemicals or resins are used in this process and the finished materials are all made with natural residual waste that would otherwise be burned. The StrawJet system is portable and can provide similar output to factories but without all of the overhead and environmental concerns.

The StrawJet invention is extremely versatile, as it can make building materials out of any naturally occurring stalk, such as bamboo, palm fronds, river weeds and wild grasses. This versatility means that it has applications just about anywhere in the world. The resulting building materials also offer better insulation than typical brick and mortar construction, are better able to withstand earthquakes and cost less to produce.

PCT/US2005/027247, PATENTSCOPE® search)

Patents

Recognizing that he had developed a technology that could completely change the way sustainable buildings are made, Mr. Ward and ASET knew that protection of their intellectual property (IP) was important. In 2005 they filed a patent application for the StrawJet invention with the United States Patent and Trademark Office (USPTO). In the same year, they also filed an international application under the Patent Cooperation Treaty (PCT) system.

Commercialization

StrawJet, Inc. (StrawJet) was formed in 2004 to commercialize and manage all aspects of the StrawJet invention. The company markets its products as the StrawJet System and sells four major pieces of machinery, along with supporting equipment. Their first product is the StrawJet Cable Machine, which is the flagship product and is the machine that produces the unique cable from agricultural waste. The second product is the Multi Wrapper, which is an optional tool that converts the cables into various building materials. The third product is the Bobbin Winder, which allows string to be quickly and seamlessly wound from any source into universal spools for use in the Cable Machine and Multi Wrapper. The fourth product is Single Cable Terminator, which allows cables with several layers of wrapping string to be cut into different sizes. Lastly, the company sells three pieces of supporting equipment: bobbins (a simple tool that can hold up to 2,000 meters of wound string) to be used with the Bobbin Winder, trays for holding the straw cable and conveyers to feed material into the Cable Machine.

Partnerships

In 2008 StrawJet received a grant from the Lemelson Foundation, a private organization supporting inventors and their innovations, to produce adaptations of the StrawJet System to be used in developing countries. This grant resulted in a partnership between StrawJet and Washington State University with Total Land Care, a non-profit organization based in Malawi focusing on increasing agriculture production, food security and livelihood of small-scale farmers. In May 2008, the partnership launched a pilot program in Malawi to address the problem of illegal wood cutting, which significantly contributes to the country’s annual 500 km2 rate of deforestation. The program focused on building a tobacco drying shed completely out of harvested tobacco stalks, which would otherwise be burned. In Malawi there are over 150,000 such sheds, with each one requiring nearly one ton of wood to build and requiring replacement every two of three years. Many of these sheds are built with illegally cut wood.

The program organized a group of ten workers in a small Malawi village with no mechanical skills or training. After a one day hands-on training, management of the project was turned over to them. Each member worked autonomously, received a decent wage and was responsible for tasks such as gathering tobacco stalks, operating the StrawJet System or building the drying shed. Working similar to a microenterprise, the program was a success, and 1.5 tons of recyclable agricultural waste was used to build the shed in less than one week. With deforestation contributing to the environmental degradation in Malawi, this program proved that agricultural waste could be used in a developing country to better manage forests, lower pollution levels and increase the livelihood of entire communities. The pilot program in Malawi led to StrawJet and Total Land Care becoming part of a seven million dollar United States Agency for International Development (USAID) program to reduce deforestation in Malawi.

Research and Development

Beyond the Malawi program, StrawJet is involved in many partnerships to enhance the company’s technology. In 2008, StrawJet used its technology to help hemp producers in Alberta, Canada, rice farmers in California and wheat farmers in Oregon. In the summer of 2009, the company began working with the California Straw Building Association and the Southern Oregon American Institute of Architects on using the technology for interior wall applications. The company is also working on developing more applications for its technology with Southern Oregon University and the Oregon Bioscience Association.

Through these partnerships and programs, StrawJet is continually researching new ways to make its technology better. After the conclusion of the Malawi program, the company started research and development (R&D) of a system that can power the StrawJet System by a simple bicycle or integrated with computers for automated operation. Developments such as this through R&D are an important part of the company’s strategy to continually improve its technology and make it adaptable for use in environments throughout the world.

Social Issues

The StrawJet System has significant positive implications for both the economies of developed and developing countries and the environment. Economically, it is very cost-effective for farmers anywhere in the world. The only initial cost is for the StrawJet System itself, and after that users, owners and beneficiaries can make their own building materials from readily available agricultural waste that costs nothing to use. They can also supplement their income by selling any unused materials. As shown through the Malawi program, an entire community can significantly benefit from a single StrawJet System.

Use of the StrawJet system could also revolutionize construction methods in developing countries. Afghanistan is a good example, as because it is a country that is almost devoid of building materials, most structures are built with locally available rocks. Wheat, however, is plentiful in the country, and it could be used to build cost-effective, durable and safe housing solutions while providing an economic boost to communities.

Environmentally, the potential impact of using straw or other plant stalks as building materials is huge. Carbon emissions stemming from deforestation can be significantly curbed, because the materials used in the StrawJet System would otherwise be burned. In addition, significant deforestation and carbon emissions result from using wood as building materials, as they require a lot of energy to manufacture. Minimally impacting the environment, use of the StrawJet System can help cut carbon usage from deforestation by up to 10%, thus going a long way to reduce greenhouse gas emissions.

Business Results

In a very short time, the StrawJet System has attracted significant international attention. In 2006 it won the Modern Marvel of the Year Award from the United States National Inventors hall of Fame. The company’s innovative technology and EPA grant have attracted significant investment. With the completion of manufacturing for its integrated product line in 2009, the company has enjoyed international sales success, allowing it to offer preferred stock to investors and venture capitalists.

Innovation with Worldwide Impact

A true example of innovation with positive social repercussions, the StrawJet System has the potential to forever change the way buildings are constructed. IP protection has allowed Mr. Ward to refine his invention and market it internationally without fear of infringement. Providing a plentiful and cheap way to manufacture building materials from waste, it has the unique ability to curb deforestation, help the environment and better the livelihood of people in both developed and developing countries.

Source: WIPO

Client Focus

Client Focus