Background

Mr. Hiroo Nakayama spent the first 10 years of his career at the overseas steel trade division of a major Japanese shosha (trading company), after which he joined an electroforming company, where he learned electroforming technology.

and the founder of Tefco

Aomori, shares his IP

experience (Video: WIPO)

Video

In the late 1980s, the Japanese watch industry was suffering from the aging of index assembling professionals as well as a technology shift to other countries. This prompted one of Mr. Nakayama’s clients to ask him whether a solution could be found for the lack of young professionals in watch-dial-making.

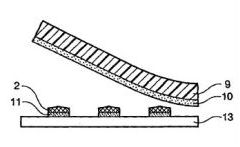

Traditionally, watch-dial index assembling was a very technical and time consuming process, requiring the full attention of a skilled worker for 10 minutes to apply the figures onto the dial of a single timepiece. This question inspired Mr. Nakayama to research a new plating technology and he came up with the idea of developing a “removable” plating letter. However, despite his wish to continue, his research was regrettably suspended by the company due to other important business. Thus, in 1988 he decided to start his own business and founded Tefco Aomori Co. Ltd. (Tefco Aomori).

Patents

Mr. Nakayama’s research efforts came to fruition in 1994, when Tefco Aomori filed two patent applications for electroforming techniques used to form and transfer metallic “sticker-like” letters. These “stickers”, named “Tefco Mirror”, are used to fix characters to small objects, such as watch-dials, as well as brand logos for high-quality goods. Patent applications for the techniques were filed in China, Germany, Japan, the Republic of Korea, Switzerland, Taiwan (Province of China) and the United States. In 1998, the company filed an international application jointly with a major Japanese watch company, CITIZEN, under the Patent Cooperation Treaty (PCT) system. “Tefco Mirror” quickly established its reputation and became widely known as a groundbreaking invention in the watch industry as it shortened the watch-dial making process from more than 10 minutes to just five seconds.

The company has continued to file patent applications to protect new inventions and in total holds 14 patents (including joint ownership) as of May 2010. Mr. Nakayama asserts that holding patents is essential for small and medium-sized enterprises (SMEs) to deal with world-class companies on an equal basis. The company employs the services of a patent attorney office to assist it in filing patent applications, negotiating with foreign clients and dealing with counterfeiting issues abroad.

Financing and Research and Development

During Tefco Aomori’s first five years of operation (1988-1992), as much as 90% of the production was defective and the company suffered severely from a deficit amounting to JPY 240 million (approximately CHF 2.8 million). The company got through this difficult period with the support of research funds from CITIZEN, a Japanese watch manufacturer. During the following five years, the company started receiving orders from watch companies as a result of the successful registration of its patents and increased recognition in the industry.

This temporarily improved the company’s financial situation until it was faced with drastically reduced demand from watch manufactures due to changes in consumer behavior leading to the greater use of time-indication functions on mobile phones and reduced purchases of watches from the late 1990s on. This change prompted Mr. Nakayama to invest JPY 10 million (approximately CHF 118,000) in research and development (R&D) of a super-flat, stainless “Tefco S Mirror”, despite the still difficult financial situation of his company. In 2002, with the new “Tefco S Mirror”, the company successfully enlarged its customer base beyond the watch industry (which was generating fewer orders due to the decline in the watch market) to the electric and automotive industries.

Business Results

The company’s patented technology is used for dials of premium watches (e.g., BVLGARI and ROLEX), as well as for placing brand logos on world renowned products (e.g., from APPLE, JAGUAR, SHARP and SONY). According to the company, annual output is approximately six million for watches, seven million for electrical appliances and one million for automobiles. Tefco Aomori employs 53 workers (as of May 2010) and is connected to approximately 30% of the world’s premium-watch market. Annual sales in March 2010 reached JPY 544.3 million (approximately CHF 6.4 million ).

Tefco Aomori won the Minister’s Prize from the Japanese Ministry of Economy, Trade and Industry (METI) in 2006 and 2007. Mr. Nakayama also won the Entrepreneur of the Year award in the Tohoku category of the Ernst & Young Entrepreneur of the Year (EOY) Awards 2008 in Japan. Tefco Aomori acquired ISO 9001:2000 and 14001:2004 certification in 2006. Mr. Nakayama asserts that these certifications are essential to establish and continue business with foreign companies.

Success in the World’s high-end Markets with Innovation

The success factors of Tefco Aomori are the founder’s enduring passion for R&D and its exclusive techniques/products protected by patents in countries where its business partners are located. Despite several periods of hardship, the founder kept investing in innovation and got his business back on track after many years of financial difficulties. His patented products and techniques made the watch-dial making process faster and less expensive while retaining a luxury finish, which makes them very popular in high-end markets.

Source: WIPO

Client Focus

Client Focus