Background

Tramex Ltd (Tramex) was founded in 1973 by Alan Rynhart – a sales agent with entrepreneurial instincts who distributed electric instrumentation products for non-Irish companies in the construction industry in Ireland. The company’s core business is creating, manufacturing and supplying electronic measuring devices.

Tramex’s most notable achievement – and its market leading innovation – was to develop the world’s first non-destructive moisture detector in 1982. The invention originated from an observation made by Mr. Rynhart of a particular problem that arose in trying to discover the precise location of a leak – due to rainfall, for instance – in structures such as flat roofs. To help solve the problem, the entrepreneur sought advice from technical experts in a university.

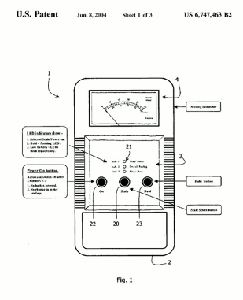

Following the experts’ advice, the sales agent manufactured a device that takes measurements at the surface level – of wood, concrete or glass re-enforced plastic, among others – without penetrating the measured object. An incision is avoided by using direct contact electrodes (an electrical conductor) which makes contact with a nonmetallic part of a circuit. Tramex’s Moisture Encounter Plus Non-Destructive Moisture Meter, can solve the challenge of finding such leaks by scanning a surface, taking an electrical conductivity measurement of it – the measure of a material’s ability to conduct an electric current – and thereby locating the problem. After satisfactorily developing and testing the moisture detector, the sales agent established a manufacturing company through which the new product was successfully launched onto the market.

Research and Development

Integral to Tramex’s research and development (R&D) strategy and market competitiveness is the company’s ability to successfully utilize not only its internal, expert team of employees, but also its pro-active employment of external partners including sub-contractors, members of the academic community and national or international agencies. The company collaborates with other organizations in order to gain state-of-the-art knowledge transfer, raise funds, and develop new products to expand and diversify its commercial portfolio.

Having identified a new market opportunity, Tramex is able seize upon it, developing an idea from inception to industrialization by using, for example, the application experiment (AE) – a proposal whereby a practical problem is solved or a new technology is designed, tested and introduced by performing industrial application experiments. In conjunction with university academics (for technical insight), national and international agencies (for fund raising and project planning), and sub contractors (for logistical and technical support), Tramex initiated a new line of products based on the transfer of cutting-edge technology developed via an AE proposal with the following organizations:

- the First User Action Program (FUSE) – a technology transfer program in microelectronics that is sponsored by the European Commission (EC) and aimed at stimulating the wider use of microelectronic technology by European companies;

- the Centre for Electronic Product Engineering at the University of Paisley (Paisley) in the United Kingdom (UK) – which has an established reputation for working closely with industry;

- the Bolton Institute (Bolton) – now Bolton University – another experienced industry partner;

- the National Electronics Test Centre (NETC) – a semi state agency established by the Irish government to facilitate the development of Irish businesses.

In 1997, Tramex approached FUSE and Paisley with an AE proposal in order to upgrade its meters from analogue to digital. This proposal came after the company carried out a market analysis study which showed that Tramex’s industry-leading position in non-intrusive moisture instruments was bound to decline due to innovations by competitors. The company had also commissioned a feasibility study through Bolton that identified the array of available technologies in the market and new opportunities for cost savings – by digitizing paper charts and records, for instance – and highlighted potential for financial expansion through marketing of digital and micro-electronic based technology.

With staff at Tramex taking the lead, the FUSE AE project – whose production to prototype stage was funded by a FUSE grant of € 50, 000 – began with a detailed project plan which included a clear time line, an analysis of the possibility of transferring the technology across the company’s range of instruments, and a cost-benefit analysis.

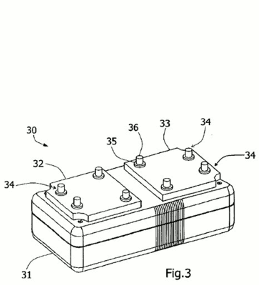

The proposed meters would be a quantum leap in the state-of-the-art, propelling Tramex into a vanguard position in the market because the device had several innovative advantages in function and form – especially when compared to the company’s old analogue technology. These advantages included a new, digital panel display, greater memory capacity based on the industry-leading technology and personal computer (PC) compatibility that allowed for data downloading and storage. The improvements would not only save the company unnecessary costs but also launch a new range of industry-leading products with the promise of healthy financial returns.

However, the company had to strike a careful balance between many competing factors including those between the cost of introducing and producing the new technology on the one hand, and on the other, the company’s and distributor’s profit margins, future costs incurred from marketing the product and protecting its intellectual property rights (IPRs), all of which affected the ultimate retail price.

Always mindful of its customers and clients, Tramex paid particular attention to the cost-benefit analysis, among other considerations, because the cornerstone of the company’s marketing strategy is to produce top-quality, low cost goods that maintain its competitive advantage over rivals whilst being attractive to and affordable for its buyers and distributors.

The company determined that the maximum viable manufacturing cost increase would be 40 percent making it necessary to consider and make provision for further costs, additional to the FUSE funding. Thus, in determining the most suitable fabrication technology, it was important for Tramex to minimize the subsequent manufacturing and industrialization costs.

With a proto-type to hand – the “Survey Moisture Encounter” (SME) -, the company moved into the product’s industrialization process which would cost an extra € 68, 000. Based on a projected increase in sales, these extra costs were recovered within 2.2 years and the return on investment (ROI) – where the benefit (return) of an invest is divided by its cost and the result is expressed as a percentage of the ratio – was estimated at around 250 percent over a period of five years.

Although the testing and production phase of the AE went to plan and was successful overall, there were some additional improvements – including revisions of designs – which had to be made before the product’s operating manual could be finalized. The cost of industrialization also covered the cost of protecting the product’s IPRs and by 1999 the product was ready for sale.

Based on past experience, the projected sales were that the product would see an initial speedy up-take in sales in its first couple of years, reach a peak, and then taper off. However, as the desire for analogue meters falls, Tramex’s digital readers would allow the company to hold a market-leading position in the new technology.

The company now has a wide range of devices with large, easy-to-read digital displays that provide straightforward solutions for measuring conductivity and humidity in materials, among other things. The devices allow professionals in the industry to make measurements for various construction purposes including flooring, building inspection, roofing, pest control, and measuring indoor air quality. Tramex is currently a leading supplier and manufacturer of hand-held measuring and surveying devices in the European Union (EU) and in the United States of America (USA).

Patents

Having spent much time and resources producing innovative products, Tramex recognizes the need to protect its inventions with patents in order to make a return on investments through licensing while retaining the exclusive right to market its goods. To that end, in 1981 the company filed patent applications in Ireland for one of its earliest moisture meters; subsequent international patent applications were filed in 1992 through the international filing system established by the Patent Corporation Treaty (PCT). In 2002 and 2003 the company also filed an application for a patent for its moisture and mould meter in one of its most lucrative markets, the USA – at the United States Patent and Trademark Office (USPTO).

Trademark

Tramex is also aware of the importance of safeguarding its corporate image, marketability, brand awareness, consumer confidence, and brand-loyalty with registered trademarks. In 1999 the company filed for a trademark registration of Tramex™ at the Office for Harmonization in the Internal Trade Market (OHIM) and at the USPTO in the USA. The Tramex brand is now readily recognized within the industry and its core products are recommended by some of the leading companies in construction including Robina Floors in the USA – a well-known manufacturer and provider of engineered wood and laminate flooring.

IP Management

Determined to protect its inventions from competitors in the industry, and aware that the company’s trademark has a world-wide good will capital that results in customer confidence and brand loyalty, Tramex established a separate company – Rynhart Research Limited (RRL)- to manage its IP portfolio. RRL files patents on behalf of Tramex and keeps track of the company’s varied IPRs portfolio in case of future IP infringement.

Partnerships

Although Tramex was initially apprehensive over its first AE project – especially over the cost and technological uncertainties involved in such an enterprise -, the company was able to allay such fears, gain confidence and know-how, make innovative technological advances, and break into new markets, by working closely with industry partners who provided tremendous financial, technological and logistic support and advice.

Among the company’s many partners at the beginning of the AE project, was the UK’s Department of Trade & Industry with whom Tramex consulted and whose “Microelectronics in Business” booklet – which contained easily understood explanations of AE projects – helped the company understand the necessary processes involved in technology transfer initiatives. Some of the many and helpful tips and suggestions contained in the booklet included a list of addresses for relevant organizations and institutions such as the “Microelectronics in Business” Support Centre at Paisley – subsequently one of Tramex’s most trusted partners.

Another important partner for the company is the Technology Transfer Network (TTN) – an industry organization whose aims, among others, are to provide independent commercialization advice to companies similar to Tramex. Following a meeting with TTN representatives, the company made a decision over the most appropriate technology to adopt for its meters, and applied not only for the FUSE funds and detailed project plan, but also to Bolton for the feasibility study which showed the AE project to be viable by providing detailed costs and market studies, further reassuring the company over its initial apprehension.

In order to promote its market knowledge and extend its networks within the industry, the company also works in close association with organizations such as the Irish Small to Medium Enterprise Association (ISME) – of which it is a member – , the International Society for Measurement and Control and the Irish section of the Instrument Society of America – which promotes instrumentation in Ireland.

From its experiences in collaborating for the FUSE AE project, Tramex recognizes the importance of choosing the right new technology, the need to seek independent and expert advice, the indispensability of commissioning feasibility studies, and the need to have a detailed project plan with clear time-scales and costs. By being proactive, the company ensures new product are successfully introduced into market on time and on budget allowing the company to maintain its market position as a low cost, top quality instruments maker.

Tramex’s strong reputation for engaging in productive industrial partnerships in order to innovate new products for new market needs has led to an ever-widening list of collaborations including that with the Oak Ridge National Laboratory (ORNL) – a multi program science and technology laboratory of the USA Department of Energy.

Business Results

As moisture measurement of building materials is a vital element in the construction process, Tramex – which now has a range of products measuring conductivity and humidity in materials – gained an estimated twelve percent of the market share for moisture meters by 1994 and subsequently maintained a competitive advantage over its rivals because of its ability to manufacture relatively low cost, innovative and durable moisture meters for the industry. The company continues to use the model of identifying market opportunities and contracting experts to research and develop products in order to expand into new commercial sectors and innovate new products.

With decades of experience as an industry leader, Tramex has developed a strong reputation as one of the most creative and trusted manufacturers of hand-held, electronic devices and has close to 100,000 innovative, practical and user-friendly devices in use world-wide.

From the floor of innovation to the roof of success.

Tramex continues its outward expansion not only because of its astute exploitation of its experienced and imaginative R&D staff and comprehensive IP strategy, but also due to its strong links to industry and academia, and to national and international partners.

Source: WIPO

Client Focus

Client Focus